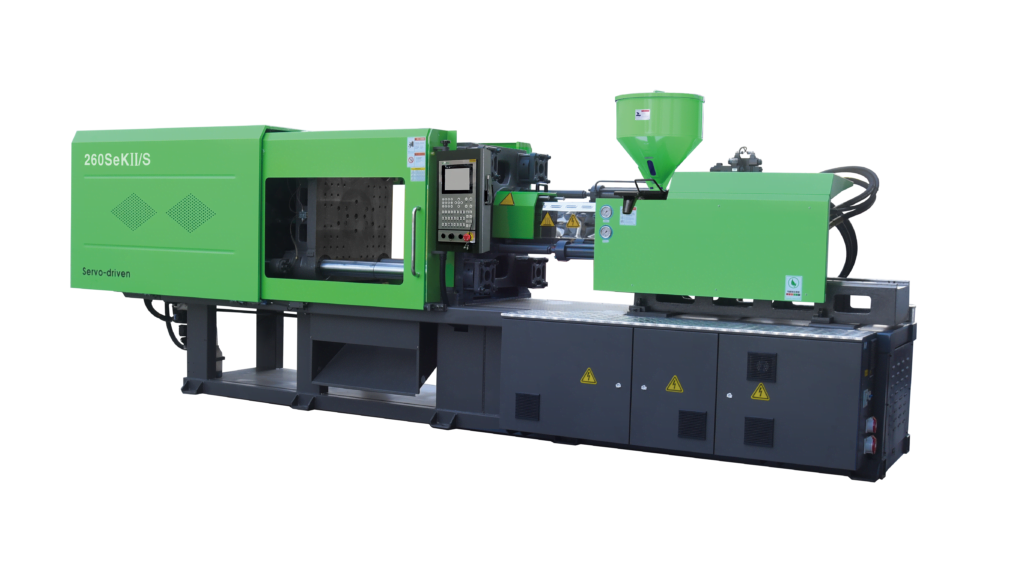

Injection Molding Machines

SANA is a leading global manufacturer of high precision injection molding machines.

V70 Controller – 19″ True Split Screen with Touch/Swipe Functionality

With the new Injectvisor V70, you get a controller designed with the smart factory in mind, one that’s capable of integrating with auxiliary equipment via OPC-UA communication. Packed with new tools for speeding up mold set ups, optimizing cycle times, analyzing part defects, troubleshooting molding defects and more, giving you a faster payback on your machinery investment.

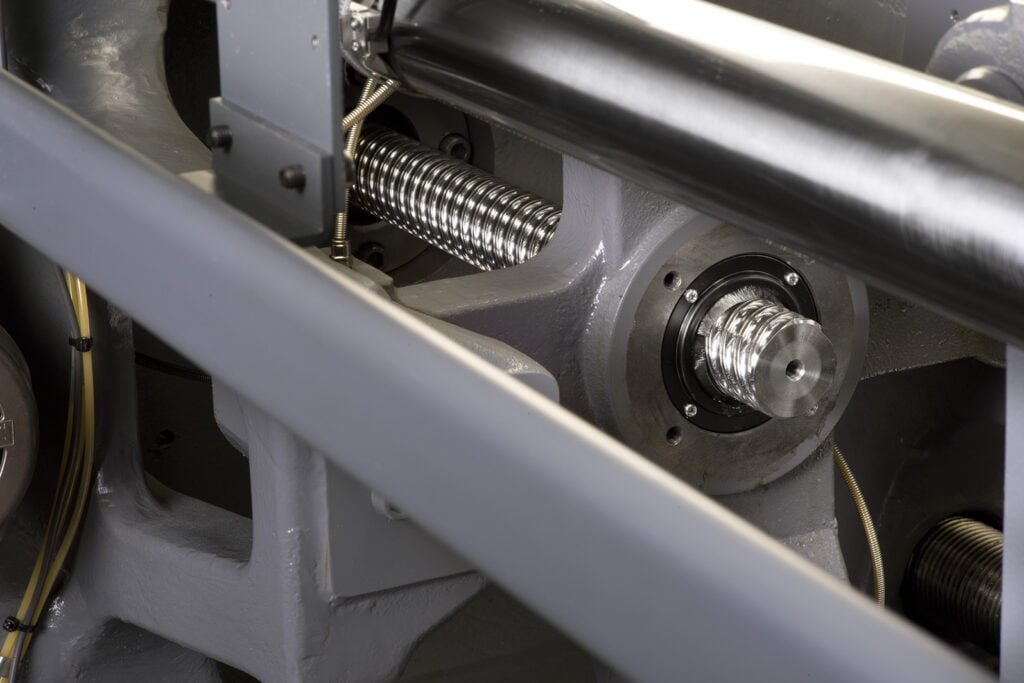

Ball Screws – uniquely designed for high performance and long operating life

Ball screws designed specifically for injection molding with a dual run of balls that spread the load over twice the area of typical ball screws. We also incorporate spacers between each ball ensuring long, trouble-free operating life.

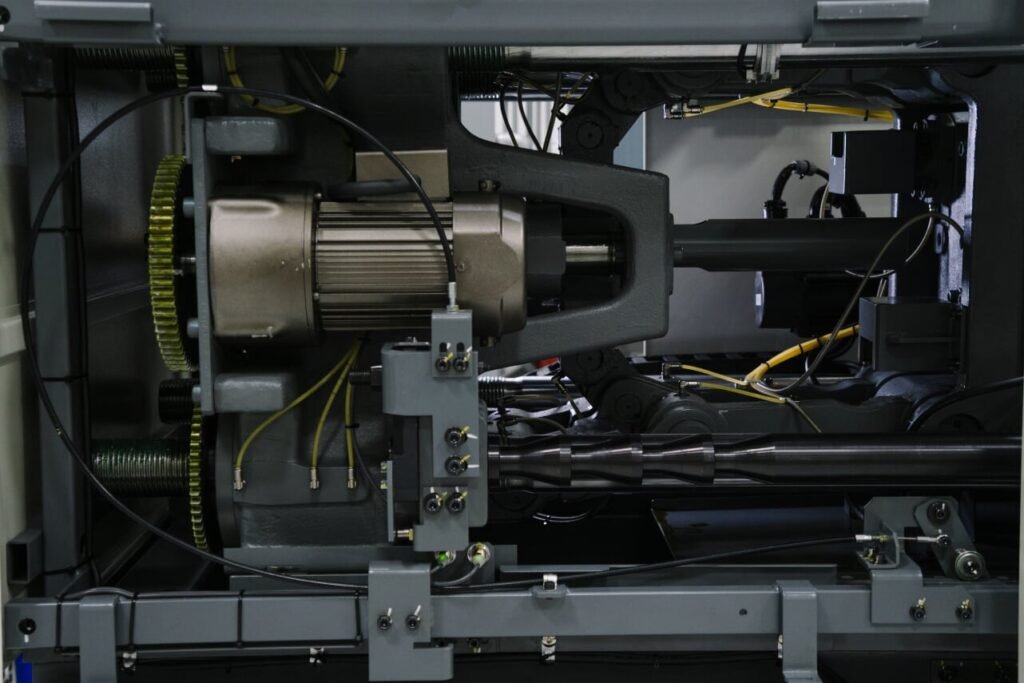

Linear Guides for Rigid, Precise Machine Movements

On the moving platen, linear guides are used instead of tie bar bushing to ensure steady, precise movement. This friction free drive system is also used on the injection unit to ensure more accurate injection speed and back pressure control. This ensures shot-to-shot repeatability over the life of the machine.

Bushing Free, Grease Free Tie Bars

With bushing-free, grease-free tie bars, there’s less chance of contaminating molded parts, increasing your shop’s quality.

5-point Linkline toggle mechanism – even force distribution, extended mold life, and reduced maintenance

The 5-point Linkline toggle mechanism is angled to distribute force evenly across the platen, increasing quality and minimizing defects. It has the added benefit of extending mold life and reducing machine maintenance.

Dual Hydraulic Core Pull Program & Electrical Interface

Our machines come equipped with dual core pull programming and interface. Portable hydraulic power units are sold separately, but can be added at any time. Our portable hydraulic units simply plug into the standard interface, for easy, “plug and play” use.